Delta PQC Active Power Filter (APF) applied in the Automotive Part Processing Industry

Industry background

Auto-making involves many mechanical processes with demanding quality requirements. Before any mechanical smelting, casting, or stamping, an induction melting furnace is used to melt metal. Most induction melting furnaces use a 6-pulse or 12-pulse rectifier, which produces high volumes of harmonic and reactive power. As a result, the production efficiency of induction melting furnaces decreases, production costs rise, and metal quality falls.

Welding, stamping, and coating equipment are indispensable for automated automotive assembly. In addition to the harmonic current, the load of such equipment changes randomly and rapidly, and the flicker and voltage dip caused by the reactive current is severe. Serious power quality problems affect both automotive production efficiency and production quality.

Customer

Shanghai GKN Drive Shaft Co., Ltd. (SDS), one of the earliest companies in the industry, and now a leading company for automotive components in China.

Power quality problem description

Thermal losses are severe for power distribution equipment such as distribution transformers, breakers, and cables. The control system and equipment efficiency of the induction melting furnace is reduced significantly. As capacity blowing and resonance problems occur to the 10KV transformer, there are high reactive power fines, and the maintenance fee and management cost of the distribution system soar. Production capacity and efficiency are significantly affected.

Cause analysis

The induction melting furnace uses 12-pulse rectification. LV voltage distortion is severe, power factor is low, losses and heat are high as the 5th and 7th orders of harmonic current flow into the transformer. The 11th and 13th orders of harmonic current all flow into the 10KV distribution system to cause voltage distortion, and higher harmonics induce LC resonance in the distribution system and capacitors.

Solution

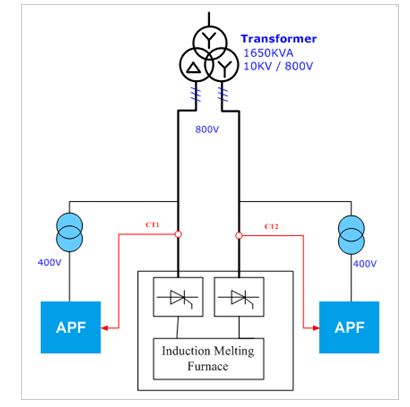

Referring to onsite inspection and pilot testing and assessment, one PQCA-400-75-750C4 is implemented to the LV side of the LV distribution system in the form of a step-up transformer as shown below:

Effectiveness

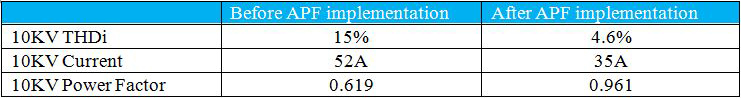

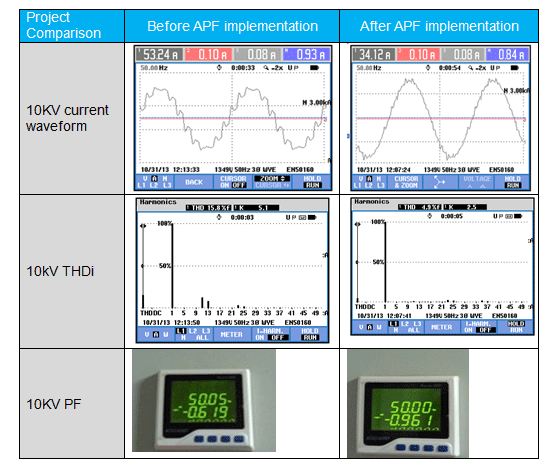

After implementing the APF on the LV side of the distribution system, system operation is significantly improved. The following data shows the actual performance before and after APF implementation.

The department’s empirical data before and after PQC APF implementation is as follows:

Conclusions

After implementing Delta’s PQC APF on the LV side, power quality of the 10KV system was improved, and the power quality of a group of LV systems were resolved as discussed below.

- After compensation, harmonic content complies with the domestic GB/T14549-93 standard, the THDi of the 10KV system decreased to only 4.6% and the apparent current was reduced by 32%.

- Transformer in-load capacity was effectively enhanced. Transformer and busbar overheating and noise were basically eliminated.

- Equipment usability enhanced. The safety and reliability of the distribution system and production equipment operability were all enhanced.

- The reactive penalty before APF implementation changed to reactive reward, and investments can be recovered in three years from the energy saved from all nodes and electricity bills.

Site deployment