How does an SVC work?

Each SVC system is tailor-made to fit the network fault level and load parameters.

The Delta Electronics Static Var Compensator’s state-of-the-art high voltage thyristor valve, reliable controller, modern user interface and redundant technical design are combined into a fast, reliable and robust system that is easy to operate and complies with all standard communication protocols.

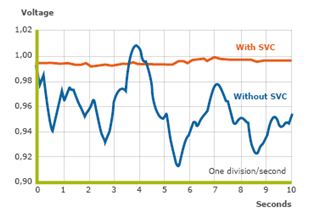

The Static Var Compensator is connected parallel with the load to be compensated. The system provides reactive power in proportion to the system supply voltage.

Thyristor-controlled reactors (TCR) generate SVC’s inductive power and passive filter capacitor banks generate its capacitive power. As TCR also generates harmonic currents, the capacitor banks are fine tuned for not only reducing harmonics generated by the load but also from the system itself.

The thyristors are net commutated thus they can be turned on once per cycle. This feature along with the control and measuring strategy define response time for reactive power and voltage changes. When open loop control strategy is implemented, the typical response time of the SVC system is 10ms (50Hz).

Delta Electronics control & protection system guarantees superior performance for flicker mitigation, reactive power control, power factor control and voltage stabilisation. Advanced protection system ensures that the components are well protected against unexpected system fault conditions. Master controller regulates the operation of thyristor valve in order to respond to the system’s reactive power requirements.

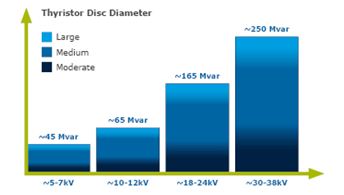

Widely adjustable power range

The system can be built for all medium voltage levels starting from 3.3kV all the way up to 38.5kV. The power output range starts from 4Mvar up to 250Mvar and the systems can be connected parallel for a higher total output.

Innovative Features

In the heart of the system is Delta Electronics thyristor valve that is developed to meet the demands of performance and reliability in harsh industrial environment. Due to its mechanical composite construction, the size of the valve is compact and it can be installed even in a standard sea freight container. The electronics are simple and robust, but the device is still equipped with comprehensive monitoring and electrical protection features. All communication between high voltage thyristor disc level and ground control system is utilizing fibre optics which makes long distance signal transfer possible.

Innovative design and reliability

-

Delta Electronics thyristor valve is compact and robust due to its innovative mechanical composite construction

-

Fibre optics based communication between high voltage thyristor disc level and ground control system makes long distance signal transfer possible

-

Due to compact valve design a system can be built in a standard container and is easily re-locatable.

-

Advanced protection system ensures that the components are well protected against unexpected system fault conditions

Sophisticated monitoring and remote access

-

The system can be monitored and controlled remotely or at on-site workstations

-

Comprehensive monitoring and electrical protection features

-

Advanced and easy-to-use user interface with 19” touch screen

Effective control strategy

-

Open and close loop control strategies permit effective fl¬icker mitigation, reactive power control, power factor control and harmonic mitigation

-

Proven control algorithms

Delta Electronics Power Quality System

-

Delta Electronics Power is an ISO 9001:2008 certified company.

What we offer

Typical Delta Technocrats SVC project activities include:

-

System studies and indepth analysis

-

Engineering, simulations and design

-

Factory tests for validation of required criteria

-

On-site delivery, installation and commissioning

-

Training and after-sales support

-

Modernisation and upgradation

Choosing between Delta Electronics STATCOM and Delta Electronics SVC

Delta Electronics STATCOM and Delta Electronics SVC both are proven and reliable solutions to solve power quality challenges. To select the right solution for your specific power quality challenge and application, please feel free to contact us. Our experts will be happy to analyse your power quality challenge and suggest the right solution.