Delta PQC Series Active Power Filter (APF) Applied in the Metallurgical Industry

Industry background

Dynamic reactive power, low power factors, and high harmonic content are common power quality problems in the metallurgical industry. Major contamination sources of power quality include the arc furnace, induction melting furnace, rolling mill, and electroplating, which contains rectification loads. The operation of an arc furnace is complex. During smelting and refining periods, harmonic current is irregular. When harmonics occur, dynamic reactive current and 3-phase imbalance are produced. The 3-phase arc furnace is commonly used in steel smelting and the single-phase arc furnace is often used in copper and copper alloy smelting.

During the smelting period, the power factor of arc furnace is below 0.7, and even drops to 0.1 after a short circuit. During the refining period, the power factor is only 0.8. Voltage fluctuates as reactive power is dynamic, and this can have a great impact on the grid and influence the normal operation of other loads.

Customer

Jiangxi Copper Group (JCG), the largest copper product manufacturer in China.

Power quality problem description

JCG uses non-linear dynamic loads, such as arc furnaces and electroplating, extensively during copper smelting, and major problems include:

- The dynamic harmonic and reactive currents that cause grid voltage to fluctuate.

- Frequent failure of capacitor banks and reactive penalties from the power distributor due to low PF.

- Voltage distortion that exceeds national standards due to harmonic current.

- High maintenance costs due to high equipment failure rates.

Solution

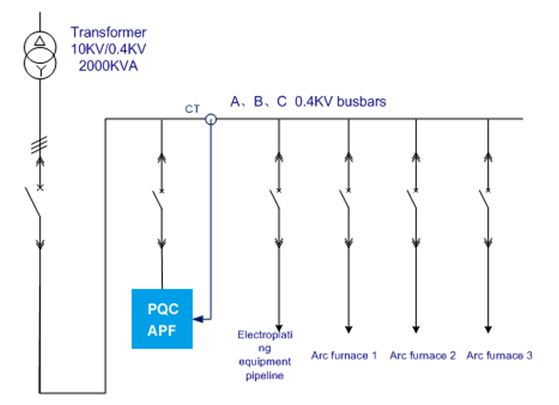

Dynamic reactive and harmonic current management are implemented on the arc furnace connected to the LV distribution side. One set of Delta PQC series APF (single unit capacity 750A) was implemented as shown below:

Effectiveness

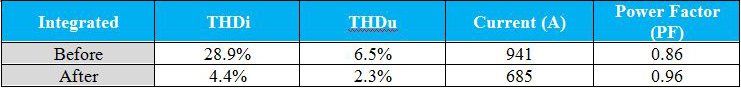

The effectiveness of the PQC active power filter was significant, as shown in the data below:

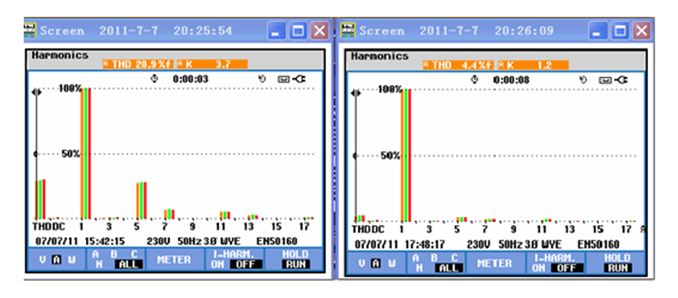

Current THD before and after PQC implementation is as follows:

Voltage waveform and PF before and after PQC implementation are as follows:

Conclusion

Delta’s PQC APF has been running steadily at JCG for over two years. PF is steady at over 0.96; current THD was reduced from 28.9% to 4.4%; and current, voltage, and PF are now better than the national standard and power distributor requirements . The failure rate of both the arc furnace and electroplating equipment were significantly reduced. By decreasing the apparent current, thermal losses of the circuit were reduced. Meter monitoring shows energy saved to a specific degree. No resonance of the capacitor banks is reported for secure grid stability.